Silicon, the fundamental building block of modern electronics, plays an indispensable role in our daily lives. From the tiny transistors in our smartphones to the intricate circuits in our computers, silicon is the unsung hero of the digital age. Behind this ubiquitous material lies a complex and fascinating world of Silicon Manufacturing, and in this article, we will embark on a journey to unravel the secrets of Silicon Wafer Production in California.

The Silicon Valley Connection:

Silicon Valley A Global Technology Epicenter

Silicon Valley, located in Northern California, is synonymous with innovation and technology. It’s the birthplace of giants like Apple, Google, and Facebook. But have you ever wondered why it’s called Silicon Valley? The answer lies in its historical connection to silicon manufacturing.

- The Silicon Connection

In the 1950s and 1960s, Silicon Valley was primarily known for semiconductor manufacturing. Silicon, due to its unique properties, became the preferred material for making transistors, the building blocks of modern electronics. This sparked a boom in silicon manufacturing companies in the region, giving birth to the name “Silicon Valley.”

- The Role of Silicon Wafers

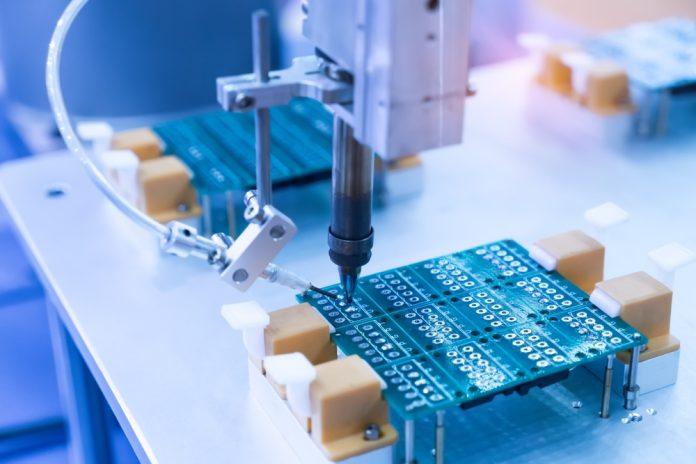

Silicon wafers are the foundation upon which semiconductor devices are built. These wafer-thin slices of silicon are engineered with extreme precision to serve as the substrate for integrated circuits. In the heart of Silicon Valley, you’ll find companies specializing in silicon wafer manufacturing.

Silicon Manufacturing Process:

From Sand to Silicon Wafer A Journey of Transformation

- Extraction of Silicon

The journey of silicon manufacturing begins with sand, specifically, silicon dioxide (SiO2). Sand is the primary source of silicon, and extracting pure silicon from sand is the initial step. The most common method used for this extraction is the Siemens process, which involves heating sand with carbon to produce metallurgical-grade silicon.

- Refining Silicon

Metallurgical-grade silicon is not pure enough for semiconductor applications. It contains impurities like iron and aluminum. To achieve the required level of purity, a refining process called the Czochralski process is employed. In this method, the metallurgical-grade silicon is melted and slowly pulled from the melt to form a single crystal ingot of pure silicon.

Wafering Process

Once the pure silicon ingots are obtained, they are sliced into thin wafers using a process known as wafering. These wafers are usually between 200 to 300mm in diameter, depending on the application.

The Importance of Precision

Precision is paramount in silicon wafer manufacturing. The wafers must be extremely flat and have a uniform thickness to ensure the success of the subsequent semiconductor fabrication processes. Even a slight variation in thickness or impurity concentration can lead to defective semiconductor devices.

Silicon Manufacturing Companies in California:

Leaders in Silicon Wafer Manufacturing

California is home to some of the world’s leading silicon wafer manufacturing companies. These companies have established themselves as key players in the global semiconductor industry.

- Applied Materials Inc.

Applied Materials Inc., headquartered in Santa Clara, California, is a global leader in materials engineering solutions for the semiconductor industry. They provide advanced equipment and technologies essential for silicon wafer production.

- Lam Research Corporation

Lam Research, based in Fremont, California, specializes in providing semiconductor equipment and services. They are known for their innovative solutions in silicon wafer fabrication processes.

Siltronic AG

Siltronic AG, with a presence in California, is a global silicon wafer manufacturer. They produce high-quality wafers for various semiconductor applications, contributing significantly to the industry’s growth.

Challenges and Future Trends:

Challenges in Silicon Manufacturing

- Environmental Impact

Silicon manufacturing, like many industrial processes, has environmental implications. The extraction and refinement of silicon can produce greenhouse gases and other pollutants. Companies are actively working on environmentally friendly solutions to mitigate these impacts.

- Supply Chain Vulnerabilities

The silicon industry has faced supply chain disruptions due to various factors, including geopolitical tensions and natural disasters. Ensuring a stable supply of high-quality Silicon Wafers remains a challenge for manufacturers.

Future Trends in Silicon Manufacturing:

- Silicon Recycling

As environmental concerns grow, silicon recycling is becoming a significant focus. Reclaiming and reusing silicon from end-of-life electronic devices can reduce the need for new silicon production.

- Advanced Materials

Research into alternative materials for semiconductors is ongoing. While silicon remains dominant, materials like gallium nitride (GaN) and silicon carbide (SiC) are gaining attention for their potential in high-performance applications.

- 3D Integration

3D integration of semiconductor devices promises to increase performance while reducing power consumption. Silicon manufacturers are exploring new techniques to stack multiple layers of Silicon Wafers, enabling more compact and powerful electronics.

Silicon Manufacturing’s Impact on Society:

Driving Technological Advancements

The silicon manufacturing industry’s impact on society is immeasurable. It has driven technological advancements across various sectors, including:

- Communication

Silicon-based chips power our smartphones and enable global communication networks. The rapid advancement of mobile technology owes much to silicon innovation.

- Healthcare

Silicon plays a vital role in medical devices, diagnostics, and imaging equipment. It has improved patient care and diagnostics accuracy.

- Renewable Energy

Solar panels, a critical component of renewable energy systems, rely on silicon photovoltaic cells. The silicon industry contributes to the shift towards sustainable energy sources.

Employment and Economic Growth

Silicon manufacturing companies in California and around the world provide employment opportunities and drive economic growth. They attract talent, foster innovation, and contribute significantly to local and global economies.

Conclusion:

Silicon manufacturing has come a long way since its inception in Silicon Valley. Today, it remains at the forefront of technology, shaping the devices and innovations that define our lives. As we look to the future, silicon manufacturing will continue to evolve, addressing challenges, embracing sustainability, and unlocking new possibilities in electronics, communications, healthcare, and beyond. It is a testament to human ingenuity and a tribute to the enduring spirit of innovation that defines California’s Silicon Valley.