Introduction

Pneumatic valve systems are fundamental components in numerous industries, driving automation and enhancing efficiency in various applications. Whether you’re working in manufacturing, automotive, pharmaceuticals, or any other sector that relies on automated processes, understanding the basics of pneumatic valve systems is essential. In this comprehensive guide, we will demystify pneumatic valve systems, exploring their foundational principles and the innovative technologies that are shaping their future.

Pneumatic Valve Basics

Pneumatic valve systems are an integral part of pneumatics, a branch of engineering that uses compressed air to control mechanical motion and perform work. At their core, these systems involve the control and regulation of air flow through valves to achieve specific tasks.

Here are the key components of a pneumatic valve system:

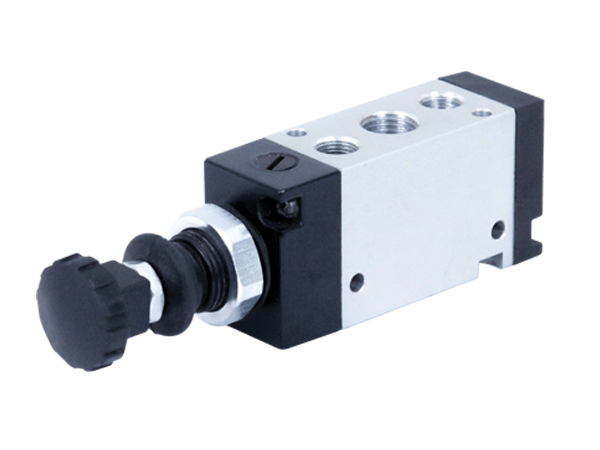

- Valves: Valves are the gatekeepers of a pneumatic system. They control the flow of compressed air, enabling or blocking it as needed. Common types of pneumatic valves include directional control valves, solenoid valves, and proportional valves.

- Actuators: Actuators are responsible for converting the energy from compressed air into mechanical motion. They are used to perform various tasks, such as opening and closing a door, moving a conveyor belt, or pressing a button.

- Compressed Air Source: Compressed air is the lifeblood of a pneumatic system. It’s typically generated by an air compressor, stored in a reservoir, and distributed to various components through a network of pipes and hoses.

- Control Logic: To automate processes, pneumatic valve systems often incorporate control logic, which can range from simple mechanical timers to advanced programmable logic controllers (PLCs). Control logic dictates when and how valves should actuate.

Applications of Pneumatic Valve Systems

Pneumatic valve systems find applications in a wide range of industries due to their reliability, precision, and cost-effectiveness. Some common applications include:

- Manufacturing: In manufacturing, pneumatic valves control the movement of robotic arms, assembly lines, and conveyor systems. They ensure precise and repeatable actions in tasks like welding, packaging, and material handling.

- Automotive: Pneumatic valve systems play a crucial role in automotive production, facilitating tasks such as spot welding, painting, and tire mounting. They help automate and streamline the manufacturing process.

- Pharmaceuticals: In pharmaceutical manufacturing, pneumatic valves are used to precisely dispense liquids, control pressure in reaction vessels, and automate pill production, ensuring product quality and safety.

- Food and Beverage: Pneumatic valves are employed in food and beverage processing for tasks like filling, packaging, and sorting. They ensure hygienic and efficient production.

- Mining: Pneumatic valve systems are used in mining operations to control the flow of materials, operate drilling machinery, and manage conveyor systems in harsh and challenging environments.

Innovations in Pneumatic Valve Technology

Pneumatic valve systems have seen significant innovations over the years, making them even more efficient and versatile. Here are some notable advancements:

- Digital Control and IoT Integration: The integration of digital control systems and the Internet of Things (IoT) has revolutionized pneumatic valve control. Companies like Airmax Pneumatic have developed smart valves that can be remotely monitored and adjusted, optimizing performance and reducing downtime.

- Energy Efficiency: Energy-efficient pneumatic valve systems are a priority for many industries. Innovations in valve design, such as low-leakage valves and energy recovery systems, help reduce energy consumption and operating costs.

- Miniaturization: Smaller and more compact pneumatic valves have emerged, allowing for the creation of smaller, more agile automated systems. This is particularly beneficial in industries with limited space, such as electronics manufacturing.

- Advanced Materials: The use of advanced materials, including lightweight alloys and composite materials, has improved the durability and performance of pneumatic valve, making them suitable for a broader range of applications.

Airmax Pneumatic: Leading the Way in Pneumatic Valve Innovation

Airmax Pneumatic is a pioneering company at the forefront of pneumatic valve technology. With a commitment to innovation and excellence, Airmax has revolutionized the way industries approach automation and control.

Here’s a brief overview of what sets Airmax Pneumatic apart:

- Cutting-Edge Product Range: Airmax offers a comprehensive range of pneumatic valves designed to meet the specific needs of diverse industries. Whether you require precision control, energy efficiency, or durability, Airmax has a solution.

- IoT-Enabled Smart Valves: Airmax’s smart pneumatic valves are equipped with IoT connectivity, allowing real-time monitoring and control from anywhere. This innovation enhances system efficiency, minimizes downtime, and reduces maintenance costs.

- Custom Solutions: Airmax collaborates closely with clients to develop custom pneumatic valve solutions tailored to their unique requirements. This customer-centric approach ensures that every system is optimized for peak performance.

- Environmental Responsibility: Airmax is committed to sustainability and environmental responsibility. Their energy-efficient valves and systems help industries reduce their carbon footprint and operate more responsibly.

- Global Presence: With a global presence and a network of distributors, Airmax Pneumatic serves industries worldwide.

Conclusion

Pneumatic valve systems are the unsung heroes behind countless automated processes, driving efficiency and precision in various industries. Understanding their fundamental principles and keeping abreast of the latest innovations, such as those offered by Airmax Pneumatic, is crucial for staying competitive in today’s dynamic industrial landscape. As technology continues to advance, pneumatic valve systems will only become more essential, providing innovative solutions to the challenges of tomorrow.