The automotive manufacturing industry always has neck-to-neck competition going on for businesses and brands. Do you know how a company retains its position in a challenging market position? It is the quality of the deliverables that make the difference. If the manufacturing and operation are up to the mark and at par with global standards, sustaining the competition gets easy.

An overview of IATF 16949 certification

The automotive industry has a dedicated certification program and QMS framework, brought by the international standardization organization or ISO. The ISO IATF 16949:2016 certification defines the competent and efficient quality management system essentials for businesses in the automotive industry. The framework brings an overview of the design and creation, production of the manufacturing parts of automotive. In fact, it also deals with the quality management of assembling and installation of automotive products. It can also be an embedded software application for the automobile.

The objective of the IATF 16949 automotive QMS standard is to materialize a setup for consistent improvement, risk mitigation, and resource management in the supply chain. It also concentrates on providing a waste management plan for the production unit. The lucrative benefits of IATF 16949:2016 certification are –

- World-class recognition for business or brand

- Enhanced customer satisfaction and client relationship

- Efficient manufacturing and production

- Improved sales and revenue

- Increased engagement for employees

- Risk management and waste reduction

The critical clauses of the ISO certification

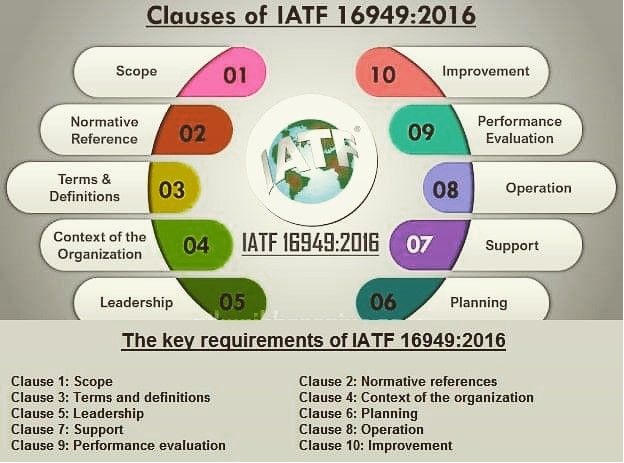

The IATF 16949 standard is segmented into ten sections or clauses. Among the ten clauses of the framework, the first three clauses cover the introductory part. The remaining seven clauses (four to ten) contain the essential traits and principles for a quality management system.

IATF Clause 1 – The scope of the certification

The first clause of ISO IATF 16949 defines the scope of the certification program. One can recognize the benefits of the certification by taking a look at the first clause of IATF 16949. Any manufacturing site for automotive parts can apply for the certification and leverage the benefits of adhering to the QMS framework.

IATF Clause 2 – Normative references

Simply put, the second clause of IATF 16949 defines the indispensable requirements. It is critical for all organizations applying for the certification or trying to accomplish the framework principles of automotive manufacturing and production quality management system. It contains normative and informative references for a well-defined control plan.

IATF Clause 3 – Critical terms and definitions

Different industries have a different set of terms and definitions, and the third clause of IATF 16949 certification defines the necessary terms. The organization owners can obtain an in-depth idea by going through the clause and enhancing their knowledge base for developing a competent quality management system.

IATF Clause 4 – Context of the organization

The fourth clause defines the context of the automotive organization and helps in clarifying the crucial factors. The organization recognizes the critical context related to the quality management system. It may include the associated parties and their requirements alongside quality-based expectations. It also defines the essentials for recognizing the scope of the system.

IATF Clause 5 – Roles and responsibilities of the leader

The fifth clause states that the management team must demonstrate leadership responsibilities for an enhanced quality management system. The clause also defines corporate responsibility and the quality management strategy. The top management needs to allocate the roles and responsibilities systematically for impeccable QMS.

IATF Clause 6 – The planning section

The sixth clause focuses on the planning attributes and defines the essentials for addressing potential risks. It also defines the opportunities and risks analysis requirements. With this clause, one can obtain a systematic overview of preventive measures, contingency plans, and lucid objectives.

IATF Clause 7 – Support and requirements

Clause seven covers the need for supporting resources and requirements. Get an overview of the requirements for infrastructure, work environment, monitoring resources, organizational knowledge, auditor competence, awareness, etc. with this clause.

IATF Clause 8 – Operational requirements

Clause eight defines the critical operational requirements concerning to planning and creation of the automotive product. With this clause, obtain an overview of planning, product requirements, designing the product or service, and controlling measures.

IATF Clause 9 – Performance evaluation and analysis

The ninth clause of IATF 16949 includes the essentials for regulating the effectiveness of the quality management system. It includes critical factors like – assessment of customer satisfaction, internal auditing steps, performance measurement of the manufacturing process, etc.

IATF Clause 10 – QMS improvement

The last or tenth clause concentrates on the consistent improvement scope of the quality management system. It includes the essentials for risk management and corrective actions, problem-solving steps, etc.

Closing note – Get certified with the correct steps.

It is critical to follow the systematic steps of acquiring the certification for an automotive-based organization. Connect to IRQS to obtain an experienced team for auditing the existing management system and make a wise choice to keep the process efficient. Get certified by recognizing the critical pointers related to the ten clauses and make the right choice.