This guide is an invaluable resource for navigating the intricacies of pneumatic valve selection and maintenance. Covering essential aspects of choosing the right valve for your application, it delves into factors like valve types, flow rates, pressure compatibility, and medium suitability. Equally vital is its insight into effective valve maintenance, outlining cleaning routines, lubrication practices, and regular inspections to ensure optimal performance and longevity. Moreover, the guide offers guidance on troubleshooting common issues that may arise during operation, ensuring seamless functionality. By following this comprehensive guide, you can make informed decisions, enhance system efficiency, and extend the lifespan of pneumatic valves in various industrial contexts.

Types of Pneumatic Valves: A Primer for Selection

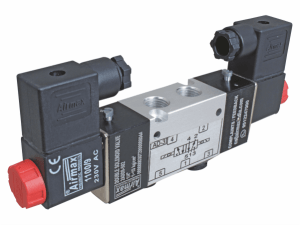

Pneumatic valves come in a range of types, each designed to serve specific functions in pneumatic systems. Directional control valves determine the direction of airflow, while pressure control valves manage system pressure. Flow control valves regulate the rate of airflow, and on/off valves provide simple start-stop control. Choosing the right valve type involves understanding the needs of your application and how each valve’s functionality aligns with those requirements.

Key Factors in Valve Selection: Flow, Pressure, and Compatibility

Selecting the ideal pneumatic valve requires considering critical factors. Flow rate is crucial, as too little or too much airflow can affect system performance. Pressure requirements should match the valve’s pressure ratings to ensure safe and efficient operation. Compatibility with the working medium, be it air or specific gases, is essential to prevent corrosion or malfunction. Evaluating these factors ensures optimal valve performance within your pneumatic system.

Optimizing Performance: Installation and Initial Setup

Proper installation is vital for valve efficiency. Ensure accurate placement, secure mounting, and appropriate connection to the pneumatic circuit. Minimize pressure drops by selecting appropriate pipe sizes and avoiding sharp bends. Calibrate any adjustable settings according to system needs. By meticulously following manufacturer guidelines during installation and setup, you guarantee the valve’s optimal functionality and longevity.

Pneumatic Valve Maintenance: Cleaning, Lubrication, and Inspection

Regular maintenance is crucial for sustained valve performance. Cleaning prevents debris accumulation that can obstruct airflow. Lubrication enhances moving parts’ longevity and operation, minimizing friction. Scheduled inspections identify wear, leaks, or other issues requiring attention. Proper documentation and adherence to maintenance schedules ensure the valve’s reliability, extending its service life and reducing unexpected downtime.

Troubleshooting Common Issues: Ensuring Smooth Operation

Despite proper selection and maintenance, issues may arise. Common problems include air leaks, erratic valve behavior, or inadequate airflow. Troubleshooting involves systematic checks, including inspecting seals, connections, and electrical components. Referring to manufacturer manuals can aid in identifying and addressing issues. Regularly training personnel on troubleshooting procedures ensures swift resolution, minimizing disruptions to your pneumatic system’s operation.

Conclusion:

In conclusion, understanding the types of pneumatic valves, considering key selection factors, optimizing installation, performing regular maintenance, and having effective troubleshooting strategies are all integral to ensuring a well-functioning pneumatic system. Selecting the appropriate valve type for your application’s needs lays the foundation for efficient operation. Key factors like flow, pressure, and compatibility dictate valve performance. Careful installation, combined with diligent maintenance and troubleshooting practices, contributes to sustained operational excellence and longevity of the pneumatic valve. By adhering to these guidelines, you can maximize the performance and reliability of your pneumatic system, ultimately contributing to enhanced productivity and efficiency in various industrial applications.