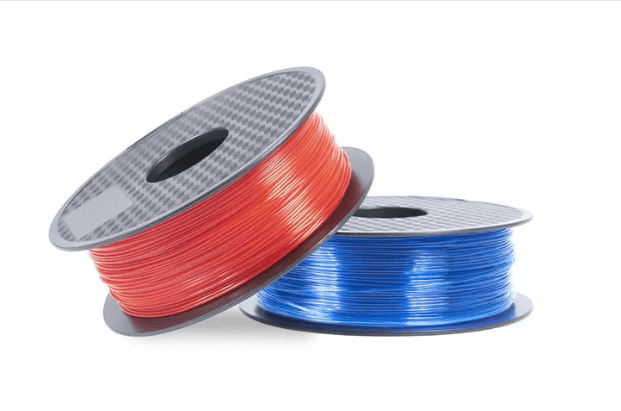

3D printer filament is a kind of printing material used by Fused Deposition Modeling (FDM) 3D printers. It is among the most often-used 3D printing material for 3D printing. The filament is produced into one continuous slender plastic thread in hundred meters long, spooled into a reel for the purpose of storage and printer feeder. One spool is typically equal to 1 kg. There are various facts about filaments that are worth knowing; they include the following;

- Filaments used in 3D printing are thermoplastics that melt rather than burn when heated; hence they can be easily shaped and molded and solidify when chilled. The filament is fed into a warmup chamber in the printer’s extruder assembly. It is heated to its melting state and then extruded through a nozzle as the extruder assembly moves, following the path programmed into a 3D object file to create the printed object layer by layer. The process of printing thermoplastics is called FFF fused filament fabrication or Fused Deposition Modeling; they are the same.

- Filaments are categorized into two standards a 1.75 mm radius and a 3 mm radius. The 1.75 mm radius filament has dominated the market share between the two standards. Why? It is because it offers a better printing performance, such as extrusion flow consistency. They are sold in spools with a length of 330 meters.

- There are various filament types, and each has different printing temperatures and properties, which will be discussed later. Primarily, FDM printers provide a printing temperature between 190 degrees to 260 degrees Celsius, a basic plastic filament printing. Still, some more advanced filaments require higher printing temperatures; these types of filaments also need a higher or advanced 3D printer, primarily industrial 3D printers.

- 3D printer filaments are used in various applications. It indeed has some limitations, like mechanical dimensions, but they are instrumental in prototyping several products. Prototyping is the most common application, which requires lower mechanical properties from the material itself. For the same reasons, many business personnel and professionals choose thermoplastic materials for jigs and fixtures, props, assembled parts, toys, education models, and much more. But TPU filament is under flexible filaments and is mainly used for functional elements, especially in footwear industries. This industry enjoys using TPU because of its rubber-like properties, which are a vital requirement for the material mechanical property.

The 3D printer filaments may look the same and are easy to manufacture from outer appearance, but note that the quality matters greatly. The filaments have various radius varieties; the enormous variety will deliver poor printing performance, such as surface quality and part accuracy. Some things impact the printing performance and result in quality. They include;

- Material purity

- Spool winding

- Batch consistency

- Moisture absorbance

You will notice the sensitivity of these factors in different application scenarios and filaments. For instance, TPU is quite sensitive to moisture and radius variety, especially when using it to print shoe upper face. Notice that when the material absorbs moisture quickly during the making process will result in vapor busting from inside and leads to a lag between extruded thread. On the other hand, a spool with too extensive a variety range can cause an uneven extruded thread and lead to broken fabric.

Therefore, having these facts about 3D printing filament will help you choose the best filament for your application and know what to avoid during printing with certain filaments. To learn more about the filaments, visit the Snapmaker website and make your order Read more