Pneumatic valves are an integral part of many industrial processes, offering a myriad of benefits that contribute to efficiency, precision, and cost-effectiveness. These valves use compressed air to control the flow of various substances, making them indispensable in a wide range of applications. In this article, we will delve into the advantages of installing pneumatic valves, shedding light on why they are a preferred choice in numerous industries.

Understanding Pneumatic Valves

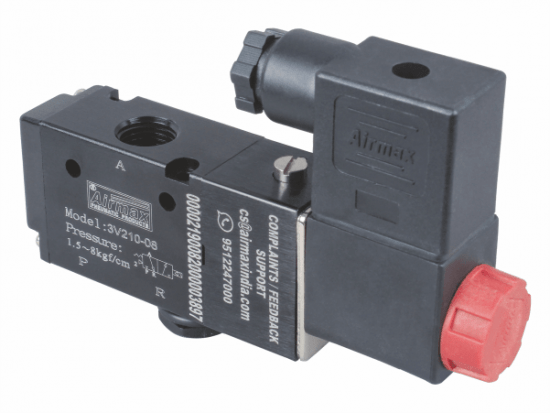

Pneumatic valves are devices that regulate the flow of air or gases through a system. They come in various types, such as ball valves, butterfly valves, and solenoid valves, each suited for specific applications. Industries like manufacturing, agriculture, and pharmaceuticals rely on pneumatic valves to control processes seamlessly.

Benefits of Pneumatic Valves

Efficiency and Reliability

One of the primary benefits of pneumatic valves is their ability to operate swiftly and consistently. These valves can open and close rapidly, leading to efficient control over the system. Their reliability is unmatched, ensuring that critical processes run smoothly without interruption.

Cost-Effective Automation

Automation is a crucial aspect of modern industry, and pneumatic valves play a pivotal role in this transformation. They help reduce labor costs by automating repetitive tasks, leading to increased productivity and reduced operational expenses.

Improved Control and Precision

Pneumatic valves offer unparalleled control and precision in regulating fluid flow. Their quick response and precise adjustment capabilities make them ideal for applications that demand accuracy, such as in the pharmaceutical and food processing industries.

Durability and Longevity

Pneumatic valves are known for their durability. Built to withstand harsh operating conditions, they are a reliable choice for industries where equipment longevity is crucial. This durability minimizes downtime and maintenance costs.

Reduced Maintenance

Compared to other valve types, pneumatic valves require minimal maintenance. This results in lower operational costs and less downtime due to maintenance activities, making them an attractive choice for many businesses.

Environmentally Friendly

Pneumatic valves are environmentally friendly due to their minimal energy consumption. They produce fewer emissions and waste, aligning with sustainability goals in various industries.

Versatility in Applications

These valves find applications in a wide array of industries, from automotive to aerospace, showcasing their versatility. Their adaptability to different conditions makes them an asset in numerous settings.

Safety Features

Safety is a paramount concern in industries, and pneumatic valves are equipped with safety features that minimize the risk of accidents. Their ability to handle hazardous substances with precision enhances workplace safety.

Choosing the Right Pneumatic Valve

Selecting the appropriate pneumatic valve for a specific application is essential. Factors such as pressure, temperature, and material compatibility must be considered to ensure optimal performance.

Installation and Maintenance Tips

To make the most of pneumatic valves, proper installation and maintenance are critical. Regular inspections, lubrication, and cleaning are necessary for their efficient and trouble-free operation.

Real-World Applications

Industries across the board utilize pneumatic valves. In automotive assembly lines, they control air pressure for various tools and machines, while the food industry relies on them for accurate ingredient dosing. Pneumatic valves are also used in medical equipment to ensure precise air and gas flow.

Conclusion

In summary, installing pneumatic valves offers a multitude of benefits, including efficiency, cost-effectiveness, precision, and durability. Their wide range of applications, environmentally friendly features, and safety enhancements make them a valuable asset to numerous industries.